The VEERA BD200SC is a small-footprint biodiesel machine engineered for efficient fuel conversion from used cooking oil and vegetable oil. It features a controlled reaction chamber, precise temperature regulation, and simplified operation, making it suitable for entry-level biodiesel production and decentralized fuel generation.

WASTE TO ENERGY MACHINE

The Waste to Energy Machine from Veera Group is designed to convert different waste streams into usable energy products through proven thermal and chemical processing methods. This integrated solution supports the conversion of waste oil into diesel, vegetable or animal oils into biodiesel, and biomass into biochar, helping industries reduce waste while generating valuable energy outputs.

Built for stable operation and long-term use, the system is suitable for recycling units, energy recovery projects, industrial plants, and commercial production facilities. With controlled processing, efficient energy usage, and dependable output quality, the waste to energy machine enables businesses to turn waste materials into profitable resources.

This solution supports multiple waste-to-energy pathways within a single operational framework, allowing flexibility based on available feedstock and business objectives.

HOW THE WASTE TO ENERGY PROCESS WORKS

The waste to energy machine operates through dedicated processing modules, each optimized for a specific type of waste conversion.

Waste Oil to Diesel Conversion

Used engine oil, hydraulic oil, and industrial lubricants are processed through controlled distillation and purification. The system removes moisture, impurities, and heavy residues to produce clean, stable diesel suitable for industrial and commercial use.

Biodiesel Production

Vegetable oils, animal fats, or used cooking oil undergo transesterification. Through heating, mixing, reaction, separation, and purification, the process produces biodiesel and glycerin with consistent fuel quality.

Biochar Production

Agricultural waste, wood residues, shells, and biomass are carbonized under controlled temperature and airflow. This process converts organic waste into high-quality biochar while minimizing emissions and energy loss.

Each process operates independently while sharing a common design philosophy focused on efficiency, safety, and durability.

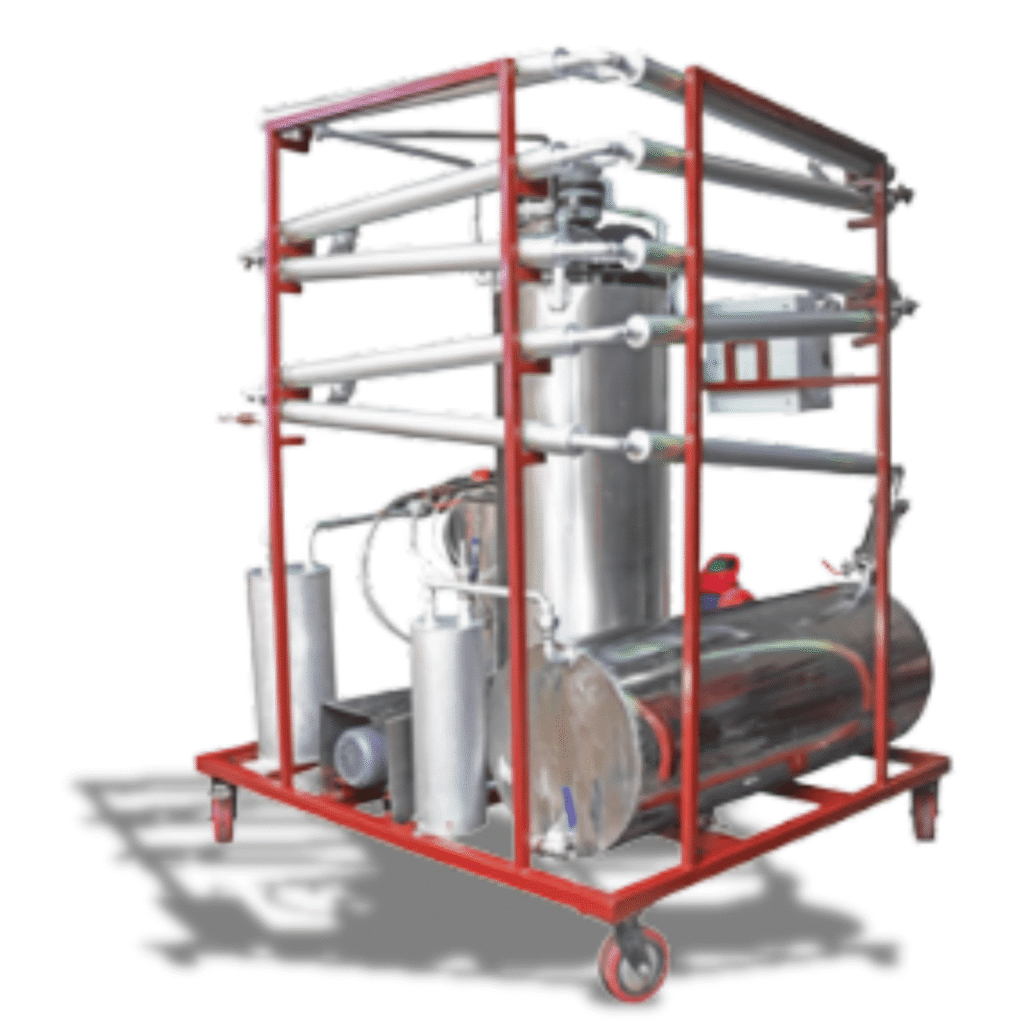

VEERA MD50SC – ADVANCED MOLECULAR DISTILLATION

$4900 / Unit

Compact and efficient, the MD50SC converts waste oil into high-quality diesel using low-temperature molecular separation technology.

The system ensures stable processing with controlled heating and safe operation.

Its design supports consistent batch performance across varying oil conditions.

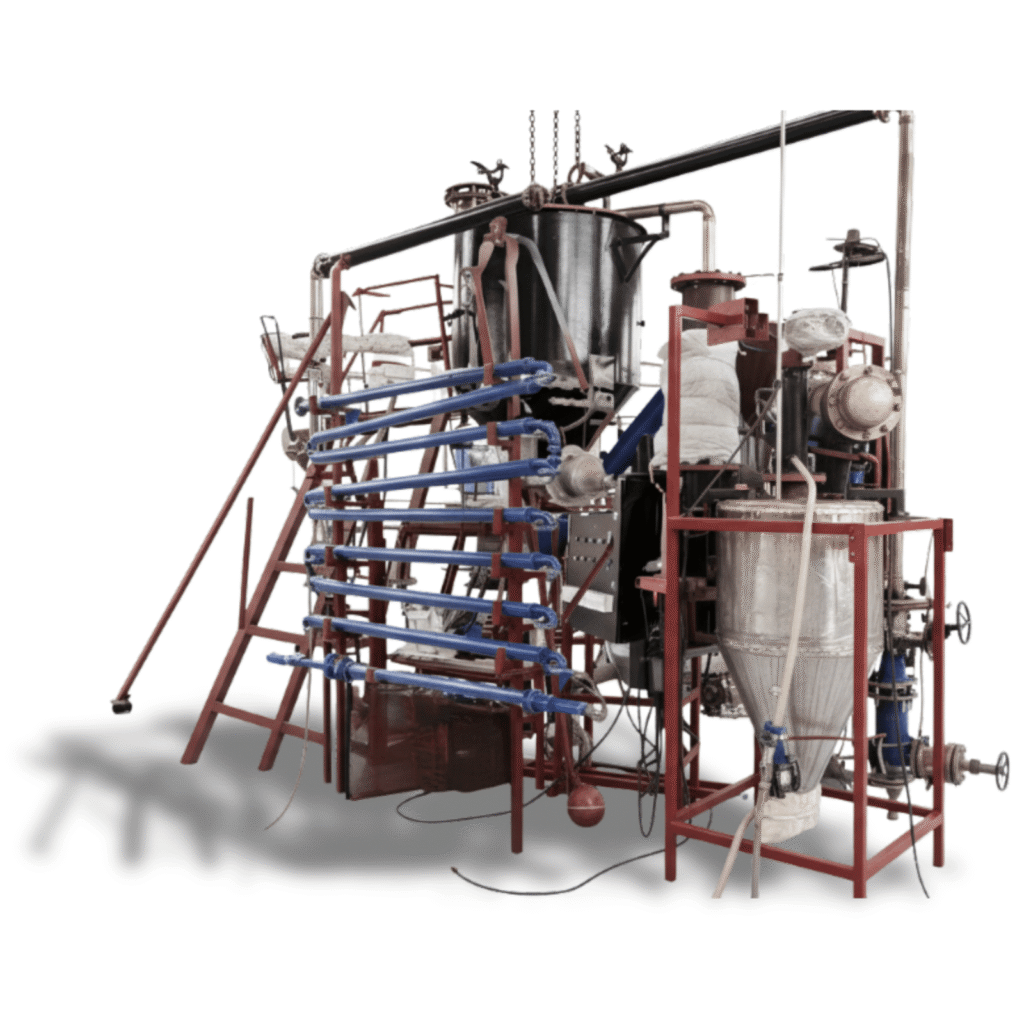

VEERA BP100C - BIOCHAR PRODUCTION MACHINE UNIT

$25000 / Unit

The VEERA BP100C is engineered for controlled biochar manufacturing using agricultural and organic biomass. Designed for steady thermal processing, this unit delivers uniform char quality while maintaining low energy consumption. Its compact industrial design makes it ideal for small-to-mid capacity operations focused on sustainable.

OPERATIONAL EXCELLENCE AND ENGINEERING HIGHLIGHTS

Designed for continuous industrial operation.

Stable thermal control for consistent energy output.

Optimized energy consumption to reduce operating costs.

Strong structural design for long service life.

Compatible with multiple waste feedstocks.

Smooth operation with minimal downtime.

Engineered for reliable performance in demanding environments.

INDUSTRIES & APPLICATIONS

The waste to energy machine is used across a wide range of sectors:

Waste oil recycling units

Biodiesel production facilities

Agricultural and biomass processing units

Industrial energy recovery projects

Environmental and sustainability initiatives

Fuel supply and distribution businesses

Municipal and private waste management operations

This system supports organizations aiming to reduce disposal costs while creating valuable energy products.

WHY CHOOSE OUR WASTE TO ENERGY MACHINE

Developed using Veera Group’s experience in manufacturing advanced recycling and energy conversion systems, this machine is built to deliver dependable output, stable operation, and long-term value. Each configuration is engineered with durable materials, refined process control, and proven technology to support consistent performance across different waste types.

The design supports flexible operation, allowing businesses to scale production based on feedstock availability and market demand. With a focus on efficiency, safety, and reliability, the system provides a practical solution for sustainable energy generation.

READY TO MOVE FORWARD WITH A WASTE TO ENERGY PROJECT?

Veera Group supports you with machine selection, capacity planning, technical guidance, and installation coordination. Share your project requirements and explore how waste can be transformed into reliable energy solutions that move your business Beyond conventional processing.

marketing.beyonddigitalagency.in is proudly powered by WordPress